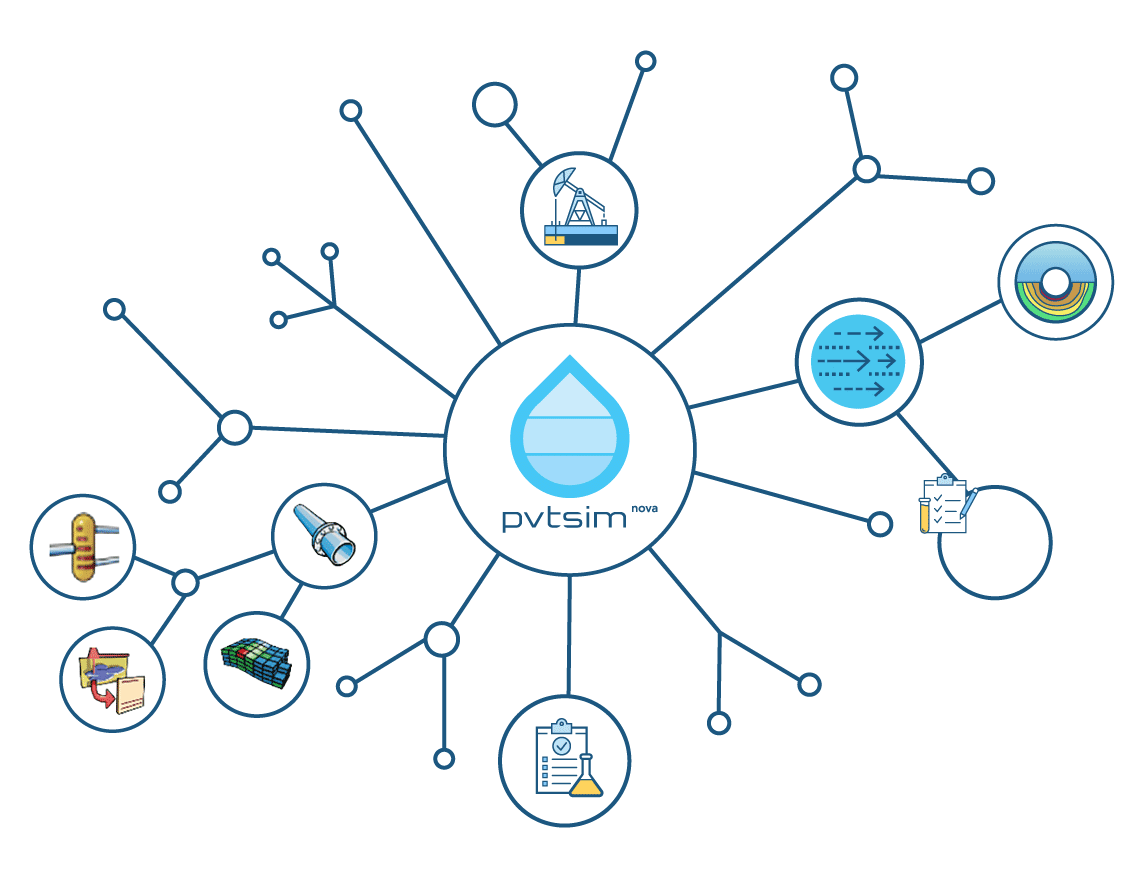

PVTsim Modules

Each of the PVTsim packages consists of a series of modules. Below is a description of the features contained in each module.

The BASE module is the gateway to PVTsim’s diverse capabilities for simulating reservoir fluid phase behavior from reservoir to refinery. Compositional analyses and PVT data from a PVT report are easily entered into and stored in a PVTsim database.

Important features of the Base module include:

• Extensive pure component library

• Input of GC and TBP compositions

• Normal and heavy oil characterization

• CSP and LBC viscosity models

• Flexible component lumping and preset lumping schemes

• Recombination of separator oil & gas

• Mixing or weaving of up to 100 different fluids

• 2 phase flash and phase envelope simulations

PVTsim may be used with the industry standard SRK or PR equations (76 or 78 modifications) in their original form or volume corrected. The GERG-2008 ensures accurate results for natural gases. More complex heavy oil phase equilibria can be handled using PC-SAFT equation

PVTsim’s module for numerical cleaning of reservoir fluid samples contaminated with oil-based drilling mud (OBM) often makes it possible to use a mud-contaminated sample in EoS modeling and thus save the operator from the expense and time it will require to take a new sample. The module includes an estimate function to find the composition of OBM contaminate and the wt% contamination when such data is not available. Contaminated measured PVT data can be input, simulated, and used in regression. The result is an EoS model for a cleaned reservoir fluid composition that can be used in simulation studies.

The reliability of the results obtained in PVTsim depends on the quality of input fluid data. The QC module is used to ensure input fluid data of good quality before proceeding with EoS modeling. A number of quality checks of the fluid data are made, including GOR/density evaluation, single-phase sample check, OBM contamination, thermodynamic equilibrium and mass balance checks of separator samples.

The results of the QC evaluations are reported in an easy-to-read Word report which includes plots and evaluation results. The report also lists possible reasons an evaluation failed.

PVTsim’s numerous flash options have been developed in close collaboration with process engineers to cover all common needs for flash specifications. The options include PT, PH, PS, VT, UV, HS, K-factor, Split-factor, P-Beta and T-Beta calculations. For systems without aqueous components, the flash calculations will typically be limited to two phases (gas and oil). For systems with water, a polar model (Huron-Vidal or CPA), can be used to give an accurate representation of the water concentration in the gas and oil phases and the amount of dissolved gas in the water phase. A PT multiphase flash option (up to 5 phases) is available for complex simulations or to reveal an unphysical model description.

A hydrocarbon fluid can be saturated by water at a given pressure and temperature. The water phase envelope option gives a complete overview of the phase boundaries for a hydrocarbon system with water and possible hydrate inhibitors.

The Flash and Unit Operations module covers simulation capabilities for the most common unit operations including compressors, expanders, coolers, heaters, pumps and valves. A multi-stage 3-phase separator option enables simulation of the amount of produced water at standard conditions from a reservoir fluid saturated by water at reservoir conditions.

The PVT Simulation & Regression module provides simulation and regression options for the below PVT experiments

– Saturation Point

– Constant Mass Expansion

– Constant Volume Depletion

– Differential Liberation

– Separator Test

– Viscosity Experiment.

– Swelling*1)

– Slimtube/MMP*1)

– Equilibrium and Multi Contact*1)

Up to 5 PVT experiments of each type can be stored with a fluid in the database. Regression options include Plus Regression and Characterized Regression. In the Plus Regression option PVTsim assists the user with suggested tuning parameters. Use the Compare with Data option to get an overview of the match of all experimental data for a fluid.

In the configuration delivered with the Reservoir Package, the module also includes powerful common EoS modeling features with regression to PVT data for up to 100 different fluids. The Multi Fluid Compare with Data option enables an easy comparison of simulated and experimental data for all fluids included in a Common EoS model.

*1) Not included in the Basic PVT Package

The property generator is a tool for generating fluid property tables in a pressure and temperature grid. The tables can be used to get an overview of how selected properties develop with pressure or temperature. The options for customizing output also make the module suited for fluid property input to software that does not have a dedicated interface available in PVTsim. The modules considers up to three phases (gas, oil and water).

PVTsim’s Hydrate module accurately simulates hydrate formation conditions of gas and oil mixtures carrying water. Depression of the hydrate formation temperature in the presence of salts and hydrate inhibitors (MeOH, EtOH, MEG, DEG, TEG) is simulated while accounting for the loss of inhibitor to the hydrocarbon phases. PVTsim automatically detects the stable hydrate structure (I, II or H) and the calculations are documented against experimental data in PVTsim’s hydrate verification reports.

The flash options (PT and PH) consider formation of hydrates (structures I, II and H) as well as gas, liquid and aqueous phases, solid salt phases, and ice. The minimum amount of a specified inhibitor to be added to prevent hydrate formation at a given pressure and temperature can be calculated with the Minimum Inhibitor option. The Hydrate PT curve option may be used to plot the hydrate curve in the relevant pressure range with or without inhibitor added.

The Wax module simulates the wax appearance temperature (WAT) of a reservoir fluid, the amount of wax formed at lower temperatures, and the total wax content in the fluid. The PT curve option gives an overview of how dissolved gas and pressure affect the wax formation conditions. The PT flash option considers gas, oil and wax phases. The wax simulations can be performed with a standard compositional analysis as input. If available, an n-paraffin analysis may be entered with the fluid.

If experimental wax data is available, it is possible to tune the wax model to an experimental WAT and/or to the experimental wax content in the stock tank oil. Non-Newtonian viscosity calculations considering the effect of precipitated wax are supported.

With the PVTsim Asphaltene module it is possible to evaluate the conditions at which asphaltene precipitation takes place. The asphaltene phase envelope option provides a complete overview of the temperature and pressure regions with asphaltene precipitation. The effect of gas injection on the asphaltene precipitation conditions can be studied using the Px-curve simulation option. It is possible to tune to experimental asphaltene data while also matching bubble point pressure data. Cubic equations of state as well as the PC-SAFT equation are available for asphaltene simulations.

The potential for scale (salt) precipitation from formation water and seawater mixtures can be analyzed using the Scale module. Water analyses are easily stored in the database and selected for simulation in the Scale menu.

The following salts are considered: BaSO4, CaSO4, SrSO4, CaCO3, FeS and FeCO3.

Pressure and temperature effects, CO2 and H2S equilibrium pressures in the water, pH as well as the effect of other ionic species (primarily NaCl, CaCl2 and KCl) are all taken into account. Pitzer’s activity coefficient model is used. 2D and 3D plot options make it straightforward to establish an overview of the scale formation conditions.

The Allocation module is used to allocate export streams of gas, oil, and water back to 2 – 100 well streams (sources). Input for each source stream is the fluid composition, meter conditions (P and T), and the flow rate at meter conditions. The source streams are mixed and processed through a user-specified separation process. The total amounts of produced gas, oil and water at standard or other reference conditions are calculated and it is output how much of the overall produced gas, oil and water originates from each source stream.

DepoWax is a compositional multiphase pipeline flow simulator taking wax deposition into account. Being fully integrated into PVTsim the user may take full advantage of the fluid handling in PVTsim. Wax appearance temperature and wax amount can be tuned up in the wax module prior to initiating a wax deposition simulation.

In addition to a properly characterized fluid composition, the input consists of pipeline data (geometry, wall material, wall thickness, etc.), flow rate and inlet conditions. Heat exchange with the surroundings and the heat of phase transitions are handled by carrying out PH flash calculations. A non-Newtonian viscosity model handles the impact of solid wax in the bulk phase. Wax is deposited over time in the pipeline by molecular diffusion. The simulation is fully compositional and well suited for simulating multiple inlets with mixing of fluids.

The PVTsim modules cover several options, but there are still customer requirements that are not honored by the usual PVTsim modules. An external software may need repeated flash calculations, or a plant-specific separation process needs to be simulated and requires a defined series of PT, PH and PS flash calculations. To meet such needs, PVTsim’s suite of modules also houses a number of libraries that can be used to build client specific applications.

These are called Open Structure modules and cover 2-3 phase PT, PH and PS flash calculations as well as for hydrate and wax flash calculations. The Open Structure dll’s come with a thorough documentation and code examples and can be called from most common program languages including C ++, C# and VB.