Introduction

A multiphase meter (MPM) is a cost-effective solution for reservoir fluid allocation. The meter provides gas and oil flowrates of a well stream at actual conditions. To take full benefit of multiphase meter readings, these meter flowrates must be converted to produced (Stock) oil and gas flowrates. Traditionally allocation calculations have been carried out using black oil correlations that allow the produced gas and oil volume flowrates:

to be derived from meter gas and oil volume flowrates

using the below equations.

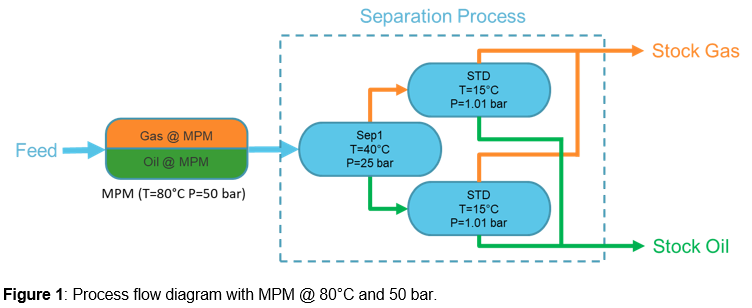

When several producers process their reservoir fluids through the same process plant, it is the allocation that defines the distribution of the revenue. An example flow diagram with a separation process is shown in Figure 1.

PVTsim has a Multiphase Meter (MPM) interface that outputs the black oil properties required to convert meter flowrates to produced (Stock) flow rates. When comparing the black oil MPM properties with those generated using one of the black oil reservoir interfaces in PVTsim, the values are found to be somewhat different. This often raises questions. This technical note explains why flowmeter black oil properties differ from traditional black oil properties and gives examples of the magnitude of the error introduced if traditional black oil properties are used instead of meter black oil properties.

Traditional Black Oil Table

Figure 2 shows a schematic drawing of how a traditional black oil table is generated. The fluid is led to a separator and split into a gas and an oil phase. To make a fair comparison with the MPM setup, the pressure and temperature in the separator in this example are the same as the MPM conditions in Figure 1 (80°C and 50 bar). The separated gas and oil streams are processed independently through the separation process, and the black oil properties are calculated using the produced volumetric gas and oil rates from each stream. As compared to Figure 1, the setup in Figure 2 has an extra separation stage (at MPM conditions).

Bg and Rv are calculated from the Gas @ MPM:

Bo and Rs are calculated from the Oil @ MPM:

MPM Bo Table

While it is relatively straightforward to derive black oil properties for the process in Figure 2, it is non-trivial to derive black oil properties for the process in Figure 1. The meter does not separate the gas and oil phases. The two phases are fed to the separation process together. As is illustrated in Figure 3, the Stock Gas and the Stock Oil both have contributions from the gas and the oil at meter conditions. In order to derive the black oil properties, it is necessary to keep track of how large a fraction of the Stock Oil and the Stock Gas that originated from the gas and the oil in the meter, respectively.

The MPM black oil properties are calculated using the below expressions.

where

is the fraction of the Stock Gas that originated from the gas at meter conditions. It is marked with an orange color in Figure 3. A similar notation is used for the volume fraction of the Stock Gas that originated from the meter oil and for the fractions of the Stock Oil that originated from the meter gas and the meter oil.

The volumes used in the above equations can be calculated from the below expressions.

where

is the fraction of component i in a stream that originates from the gas phase @ MPM,

is the mole fraction of component i in the produced gas,

and

are the partial molar volumes of component i in the produced gas and oil, respectively.

Results

Four types of reservoir fluids are considered below, a lean gas condensate, a rich gas condensate, a volatile oil, and a black oil. The general fluid properties are shown in Table 1.

Calculated MPM and traditional black oil properties are shown in Table 2. It is seen that the values are somewhat different and it is to be investigated how much that influences the conversion of flowrates from meter to stock conditions.

It is assumed that the total mass flowrate obtained from the MPM is 100kg/hr (Gas @ MPM + Oil @ MPM). The produced gas and oil volumetric flow rates can be calculated using the equations below.

The calculated Stock Gas/Oil volumetric flowrates using both the MPM and traditional black oil properties are shown in Table 3.

Table 3 also shows the flowrates simulated using the PVTsim Separation App, which is a flow sheeting tool. As seen in Figure 4, it was configured to simulate the process in Figure 1. The result from the Separation App is based on a fully compositional simulation and it therefore provides the correct rates for the produced gas and liquid.

As shown in Table 3, the flowrates calculated from the MPM black oil properties are identical to those simulated with the PVTsim Separation App. Use of a traditional black oil properties will introduce an error on the produced oil rate which varies from 1.3 – 5.1% depending on the fluid type. The impact on the gas rate is less, but still of the order of 0.5 – 0.7%.

Conclusion

Black oil properties can be used to accurately convert meter flow rates to produced flow rates, but the meter black oil properties must be derived taking into consideration that no separation takes place at meter conditions. Traditional black oil properties are unsuited for conversion of MPM flowrates because they introduce an artificial phase separation at meter conditions.